Search: desiccant / deodorant / m-buster / Food desiccant

Consultation hotline

+86 0769-83514599

1、Development history of deoxidizer

The development history of deoxidizer began in 1925 when h.a.maude and others used iron powder, ferrous sulfate and hygroscopic substances to prepare products. At that time, it was used to prevent fire and explosion of transformer and other equipment, so as to ensure safety management.

After that, people carried out the research and development of sulfite deoxidizer. Until 1977, Mitsubishi Gas Chemical Company of Japan developed a deoxidizer package based on iron powder. The deoxidizer technology was applied to the quality preservation of processed food. Since then, the application of deoxidizer in food preservation has developed rapidly.

Compared with Japan, the research and application of food deoxidizer in China started relatively late. In 1982, the deoxidizer with iron powder as the main raw material, which was researched and produced by 8511 Research Institute, began to be used in food preservation. Due to the good effect of Deoxidizer on food preservation, its application also gradually involves all kinds of packaged food. In recent years, Deoxidizer production enterprises have sprung up at home and abroad.

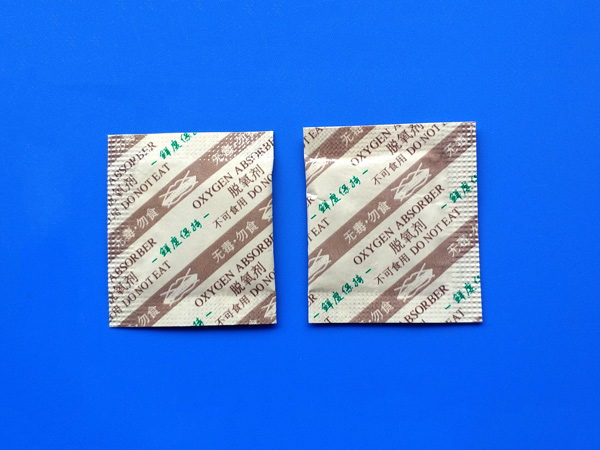

At present, there are many kinds of deoxidizers in the market, which can meet the requirements of different food preservation from the differences of packaging form and deoxidization performance. According to the raw materials of deoxidizer, deoxidizer can be divided into two categories

Inorganic deoxidizer (with iron powder, ferrous salt, sulfite and other inorganic materials as the main raw materials) and organic deoxidizer (with ascorbic acid and its sodium salt, catechol, oleic acid and other easily oxidized organic substances as the main raw materials).

Among them, the deoxidizer with iron powder as the main raw material has low price and good deoxidization performance. Theoretically, 1g iron powder can absorb 300ml of oxygen, which is equivalent to 1500ml air volume of oxygen. Therefore, iron deoxidizer is mainly used in the market now, and its oxygen absorption principle is the mechanism of iron oxidation and rust.

2、Advantages of deoxidizer in fresh keeping

(1) Deoxidizer has a good preservation effect, and different from other food additives or preservatives, it does not add to food, nor does it emit any harmful gas.

(2) Deoxidizer is odorless and tasteless, safe and reliable, easy to use, wide range of use, low price, is one of the safest food preservation technology.

3、 Application of deoxidization preservative in food

In the process of food preservation, oxygen is one of the main reasons for food spoilage. Oxygen can make mold, bacteria and other aerobic microorganisms grow and reproduce, eggs and pests grow; the existence of oxygen makes the oil, protein and vitamin in food be oxidized and deteriorated.

Deoxidizer is based on the mechanism of oxygen free preservation, which fundamentally solves the problem of food deterioration caused by oxygen, and has different effects in different foods.

The application in moon cake cake and other pastry food

Every year, there will be a bag of deoxidizer or preservative in the packaging bag of all kinds of moon cakes sold in the Mid Autumn Festival. In the process of sales and storage, moon cakes are prone to oxidation, corruption and mold growth. For example, in Cantonese style moon cakes, the moon cakes without deoxidizer packaging usually grow moldy in about one month.

The moon cakes packed with deoxidizer can keep fresh for 6 months, and the indexes of moon cakes still meet the requirements of the standard, and the smell and color do not change too much.

Cake is a common food. Because of its rich nutrition, it is easy to have mildew during storage. The cake can also be stored well by packing it with oxygen permeability less than 20ml / m2.24h.atm.

About YASHI

Company profile Equipment Honor Witness ApplicationProduct

Desiccant Food desiccant Environmental desiccant Silica gel desiccant More+News

News company Industry News FAQContact us

Feedback Recruitment Contact us

scan

scan

scan

scanService hotline:+86 0769-83514599 / +86 0769-83663597

Address:Huangjiang Park 2nd Road, Huangjiang Town, Dongguan City

Dongguan Huangjiang Yashi packing material factory Copyright Technical Support:【Dongguan Website】 【Admin】