Search: desiccant / deodorant / m-buster / Food desiccant

Consultation hotline

+86 0769-83514599

At present, the commonly used desiccant for food is silica gel desiccant. This kind of desiccant is non-toxic and environmentally friendly. The raw materials can directly contact with the food and do not cause harm to human body. It is an ideal food desiccant.

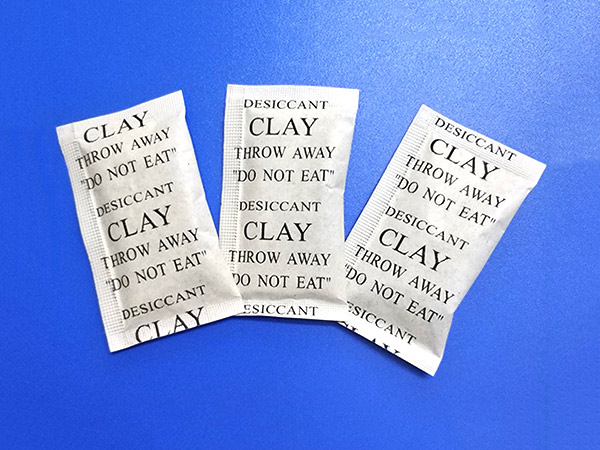

The commonly used desiccant for food is silica gel desiccant, but its best choice is mineral desiccant. Mineral desiccant - activated clay is refined from pure natural raw materials and a small amount of additives. It is green, non-toxic and tasteless. The product has good adsorption performance at room temperature and general humidity, with adsorption activity, static dehumidification and odor removal.

Mineral desiccant is mainly made of pure natural raw material minerals and a small amount of additives. It is green and environment-friendly, and has no taste and toxicity. It has good adsorption performance both at room temperature and in humid environment. There are three kinds of ingredients

The first is attapulgite

The second is montmorillonite

The third type is activated clay. The application fields of these three kinds of desiccants are also different.

Why is mineral desiccant the only choice?

Here's a look at the remarkable advantages of mineral desiccants:

1. It has a long service life and can be recycled.

2. Environmental protection, safety, can be widely used in medicine, food, feed fields. A small amount of ingestion is not life-threatening. (be careful to eat by mistake!)

3. There is no reverse osmosis after moisture absorption, which can ensure that the desiccant package is always in a dry state. There is no change in physical morphology before and after moisture absorption, and there will be no "burst package" phenomenon.

4. High hygroscopicity, strong ability to remove odor, non-toxic, tasteless, non-contact corrosion, no environmental pollution. The moisture absorption rate is 50% - 100% higher than that of silica gel desiccant. The natural structure can selectively adsorb formaldehyde and gaseous sulfide and other toxic gases.

5. Regular high-strength spherical particles can increase its fluidity, and ensure that the products will not be broken and dust will not be produced in the process of transportation, packaging and use. At the same time, even if the product is immersed in water for a long time, its strength and shape will not change, which can better improve its regeneration. Many desiccants can not be used because of saturation, the drying effect is poor, but the mineral desiccant has a long service cycle and can be recycled.

6. Compared with silica gel desiccant, the price of products with the same moisture absorption rate is much lower.

About YASHI

Company profile Equipment Honor Witness ApplicationProduct

Desiccant Food desiccant Environmental desiccant Silica gel desiccant More+News

News company Industry News FAQContact us

Feedback Recruitment Contact us

scan

scan

scan

scanService hotline:+86 0769-83514599 / +86 0769-83663597

Address:Huangjiang Park 2nd Road, Huangjiang Town, Dongguan City

Dongguan Huangjiang Yashi packing material factory Copyright Technical Support:【Dongguan Website】 【Admin】